TMT Mirror Work Continues in Japan

Despite paused construction atop Mauna Kea, work on the Thirty Meter Telescope continues remotely, in conjunction with TMT’s partnering nations.

Glass segments that makeup the telescope’s primary mirror are being produced in Japan. Over 100 of the 574 segmented mirror banks have already completed for the 30-meter wide primary mirror.

Fifty of the completed pieces have been transported to a Canon factory for surface polishing at a location about 70 miles outside of Tokyo, according to TMT officials Monday afternoon.

Polishing is currently being completed through a process from the individual mirrors created by Canon Inc and the National Astronomical Observatory of Japan.

Further research and development is underway with partnering nations China, India, and the United States for additional polishing work.

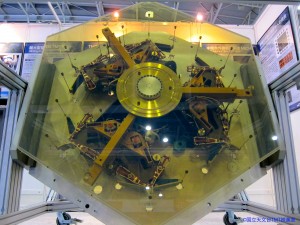

A prototype of what the individual segmented mirrors for the Thirty Meter Telescope will look like upon completion. TMT’s primary mirror will consist of 492 of these hexagonal segmented mirrors. Photo credit: TMT International Observatory.

“Japan is proud to be part of this ongoing effort in building TMT,” said Masanori Iye, vice-chair of the TMT International Observatory Governing Board and Professor Emeritus of National Astronomical Observatory of Japan. “This is an example of how people working cooperatively and sharing ideas can create positive results.”

Mirror blanks that make up the telescopes primary mirror begin with unpolished glass segments. In the TMT’s case, a special glass ceramic material, ClearCerumTM, was developed and produced by OHARA Inc. to meet the telescope’s stringent specifications and will not deform due to its zero thermal expansion properties.

According to TMT officials, the primary mirror is made up of 492 hexagonal segmented mirrors and is expected to have 82 additional spare segments.

A similar mirror design is used on the Keck telescope, however, only 36 similar mirror segments are being used.

TMT officials say that the telescope is expected to have 156 times the light gathering power and 13 times the resolving power of the Hubble Space Telescope, with sharper and deeper images than telescopes that exist on the ground and in space.

The design and manufacturing of telescope parts are being manufactured by hundreds of astronomers, engineers, and technicians from around the world, according to TMT.

“Japan’s mirror segment production is one of many important production assignments taking place,” said Henry Yang, Chair of the TMT International Observatory Board. “With work currently underway in five different regions, the TMT project is truly and literally a global effort.”

Sponsored Content

Comments